Design Brief: Modular 3D-Printed Scraper, Brush and Vacuum Nozzle for a 3D Printer

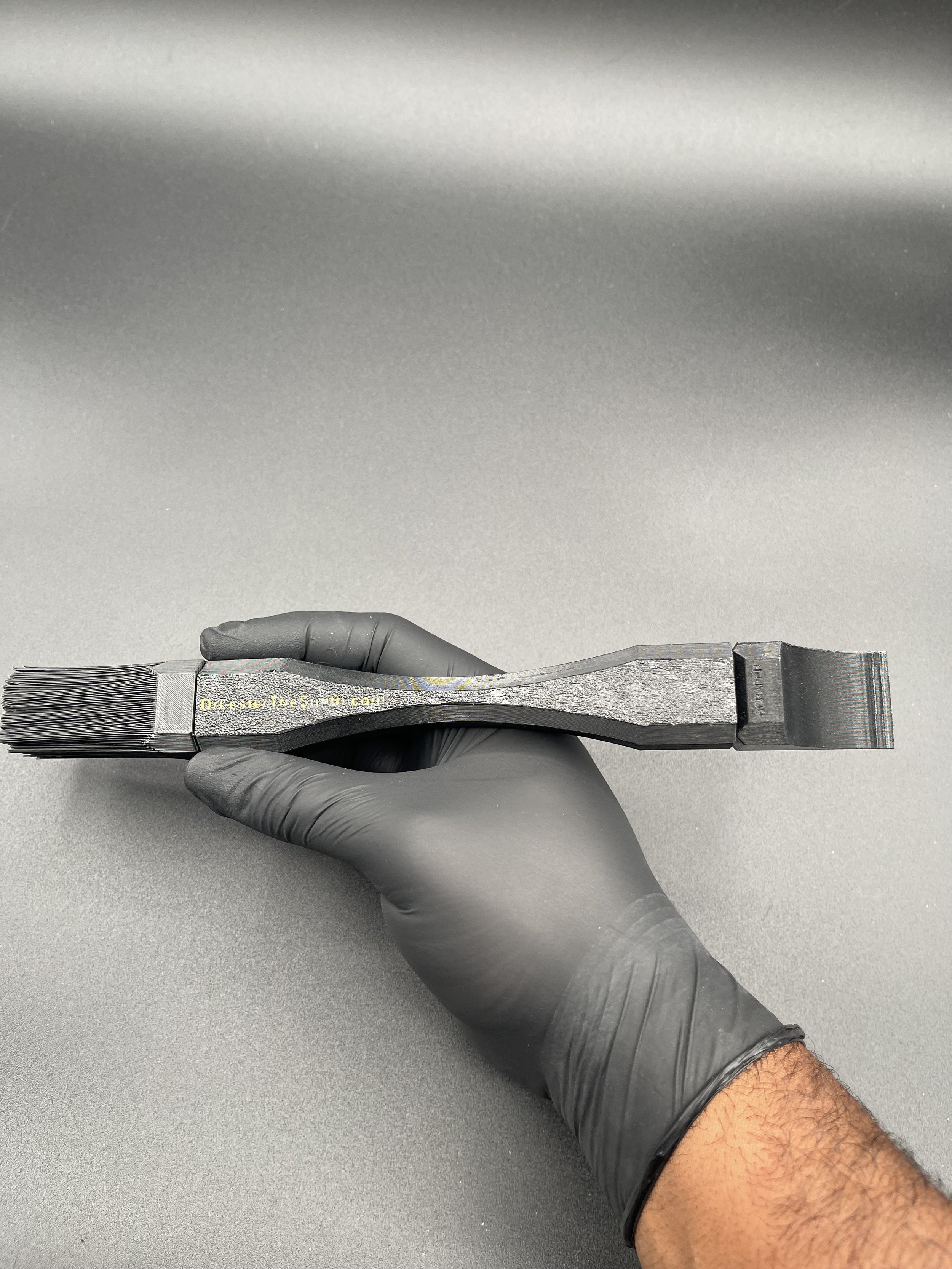

A Brush with Depth

Project Overview:

3D printing leaves purge lines and support remnants on the build plate.

Removing them is important in preparing the printer for the next print.

Plugging and unplugging mobile devices is cumbersome. Using Standby mode with a plug can lead to charge port damage and is in elegant.

Users may want an elegant solution for preparing their print bed for the next print.

Project Goal:

Design and produce a modular fully 3D printed solution for preparing a 3D printer for the next print.

Key Objectives:

Allow scrapping of 3D printing remnants from the bed of a printer.

Allow interchangeable modules for 3D printer preparation tasks such as removing adhered parts and removing small particles.

Target Audience:

FDM 3D printer users and customers who want a simple tool for cleaning a workspace.

Objective:

Design a modular system for cleaning a 3D printer build volume.

Specifications:

Assembly: Modules screwed onto a handle.

Materials: PETG, ABS, or ASA

Aesthetic: Monolithic Austere

Notable Outcome:

The Brush is entirely 3D printed.

The endcap can be twisted off after printing to free the ends of the bristles.

Updated versions have a hollow handle and vacuum modules.